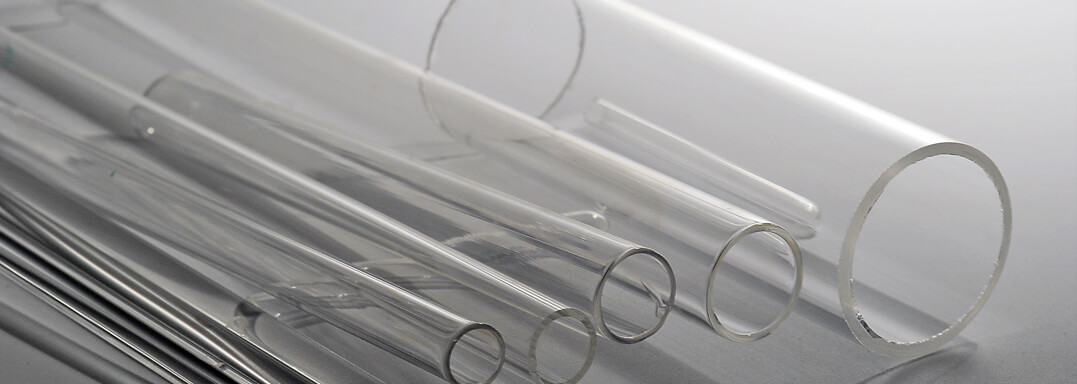

Quartz glass tubes are manufactured using heat forming technology or plasma gas method. The quartz tube is used in metallurgy and industry as an integral part of complex equipment. The material has exceptional properties, due to which the product is extensively used in various branches of modern production.

Quartz tubes

A wide range of quartz tubes for devices, equipment and apparatus for special purposes, products of chemical industry and commodities are offered by Ukrizoltisnab company. In accordance with GOST, quartz tubes are manufactured only of high-quality technical transparent glass. You may order the tubes with a diameter of 5-300 mm and with the length of up to 2000 mm. The quartz tubes can be used for fitting of boiler equipment, products for metal casting, electric heating units, lighting equipment, and equipment, which is used in the chemical and semiconductor industry.

Technical specifications:

Quartz crystal or granular quartz are used as a raw material for the quartz tube manufacture. Depending on production method and raw materials being used, the tubes are produced of the following types:

- TKGDA – the diameter of the tubes being produced is 5-300 mm. They are used for obtaining especially pure substances, reagents, devices and apparatus for special purposes, for light sources, electronic devices.

- TKGDB, TKGOB, TKGOA – the diameter of the tubes being produced is 5-300 mm. They are used for light sources, electronic devices.

- TKEOA, TKEOB – the diameter of the tubes being produced is 5-40 mm. They are used for light sources, electronic devices.

- TK – the diameter of the tubes being produced is 5-300 mm. They are used for the manufacture of products of the chemical industry and commodities.

1. The TK tubes are made of transparent quartz glass with non-standardized quality indicators concerning the bubbles and inclusions, if necessary, parameters can be specified when ordering.

Other kinds of the tubes are of higher quality. If necessary, additional quality characteristics and insignificant defects are negotiated with a customer when ordering.

2. The tubes are resistant to crystallization. When the tubes are exposured at a temperature of 1000±10°C for 2 hours with the further cooling in the air, there should be no traces of crystallization on the tubes surface.

3. The tubes are thermally stable.

When heated to a temperature of:

1000±20°C the tubes with a wall thickness from 0,6 to 3,0 mm

800±20°C the tubes with a wall thickness from 3,0 to 4,0 mm

600±20°C the tubes with a wall thickness above 4,0 mm

with the further cooling in flowing drinking water should not develop cracks, patches, spalls, chips after 15 thermal cyclings.

4. The tubes are resistant to darkening